Corrugated board manufacturers are faced with constantly growing demands on production speed and quality. Automated quality assurance processes are the key to success. Check, eject and document – the Xcam Box Monitoring systems from Baumer hhs can do it all.

Corrugated board manufacturers are faced with constantly growing demands on production speed and quality. Automated quality assurance processes are the key to success. Check, eject and document – the Xcam Box Monitoring systems from Baumer hhs can do it all.Box Monitoring includes:

Slot depth measurementRegister control

GAP measurement

Slot depth measurement

Checking the position and layout of slots

The slot depth is measured using a camera, thus determining whether the slits are in the wrong place, or missing entirely. Any cardboard fragments left in the slot can also be detected. The Xtend2 monitor displays measurements as they are taken.

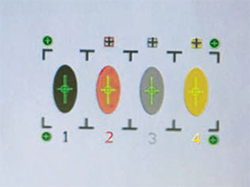

Register Control

Ensuring printing quality

Register control checks that up to six different inks are in the correct position in relation to one another. The first ink serves as the reference.

After a ten-sheet teaching cycle, a reference value is transmitted to the system. Any deviation from this is then quickly and easily detected (measuring accuracy/repeat accuracy ± 0.05 mm).

GAP Measurement

Reliably measuring and analysing gaps

This new system reliably checks the gaps created in FFG corrugated boxes between the base and lid flaps at the end of the gluing area when the four panels are brought together.

The Xcam GAP control system is based on a patented method, combining a high-resolution camera with a laser beam, making it superior to purely camera-based systems.

Regardless of whether the boxes are printed or not, the system measures the front and rear gap with millimetre precision.