GAP measurement on a Flexo Folder Gluer

GAP AUTOsys / GAP ECOsys

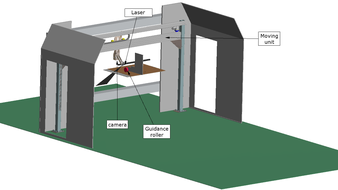

This new system reliably checks the gaps created in FFG corrugated boxes between the base and lid flaps at the end of the gluing area when the four panels are brought together.The Xcam GAP control system is based on a patented method that combines a high-resolution camera with a laser beam and, when measuring the gaps, rules out possible errors that sometimes occur in purely camera-based systems.

Regardless of whether the boxes are printed or not, the system measures the front and rear gap with millimetre precision.

An error signal can be sent to the ejector if the results differ from the reference values defined and set by the user.

This innovation from Baumer hhs increases reliability in the production of corrugated boxes and guarantees consistently high quality of the finished products, which can in turn reduce the downtime of packaging lines.

Comparison: GAP AUTOsys vs. GAP ECOsys

The two systems differ in terms of the choice of laser, the laser beam width and the automation of movement. GAP ECOsys is the more economical version, but it requires the customer to intervene manually if the gap is beyond the laser beam width of 350 mm. In contrast, GAP AUTOsys is largely automated. GAP ECOsys uses a camera with a wider viewing angle.